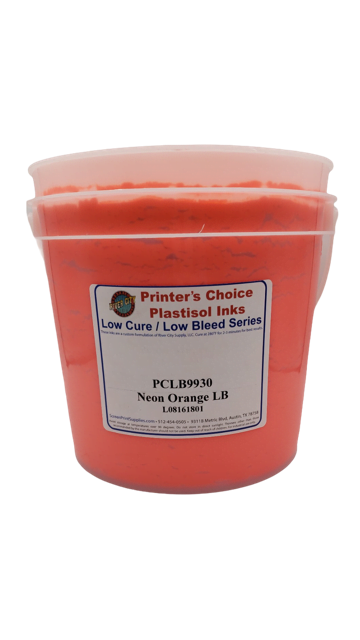

Inktek 9930 Neon Orange Plastisol Ink – Unmatched Brightness in Color

Introducing Inktek LB9930 Neon Orange Plastisol Ink – your gateway to electrifying prints that stand out with unparalleled vibrancy. Crafted to perfection, this non-phthalate finished ink strikes a harmonious balance between vivid color, creamy consistency, and remarkable opacity, ensuring optimal press performance and exceptional color design.

Inktek Neon Ink is an innovation that enhances your printing experience. The infusion of a touch of white in the formula amplifies opacity, allowing screen printers to achieve intense color brilliance swiftly, even when working with delicate mesh screen sizes. This not only delivers visually stunning results but also optimizes ink usage, ultimately saving you both ink and money.

The versatility of Inktek Neon Ink shines through. To achieve the best outcome on dark garments, we recommend underbasing the neon color with a white base. This strategic approach guarantees that your prints retain their vibrancy and eye-catching appeal, even on darker fabrics.

$44.99 – $114.99

Description

Key Features of Inktek LB9930 Neon Orange Plastisol Ink:

- Bold and Vibrant Colors: Electrify your prints with unmatched brightness.

- Opaque Ink: Ensures striking, vivid results.

- Creamy Consistency: Guarantees smooth application.

- Soft Hand Prints: Provides a comfortable feel.

- Matte Finish: Adds an elegant touch.

- Wet-on-Wet Printing Capability: Allows for seamless designs.

- Short Flash Times: Cures at a 280-degree temperature.

Inktek Neon Orange Plastisol Ink redefines the possibilities of your prints, infusing them with energy and allure. Experience a new level of vibrancy and versatility, accompanied by the ease of application and optimal results that come from meticulous formulation. Elevate your designs with neon brilliance that captures attention and leaves a lasting impression.

Technical Specifications

Inktek LB9930 Neon Orange Plastisol Ink Application:

- Substrates: Best suited for 100% Cotton and Cotton/Blends. When printing on 100% polyester, it is highly recommended to use a blocker to prevent dye migration and achieve optimal results. Always ensure the material is clean and free from any contaminants before printing.

- Mesh Selection: Choose meshes between 86 – 305 Monofilaments based on the desired ink deposit and design detail.

- Gel Temperature (Gel Temp.): Your ink should achieve a gel temperature between 155° – 165°F, ensuring that the ink has gelled properly before proceeding to the fusion stage.

- Fusion: Cure the ink at a starting temperature of 280°F for a minimum of 1 minute 30 seconds. To expedite the curing process, you can elevate the temperature. However, bear in mind that temperatures exceeding 300°F elevate the risk of dye migration, which can compromise the print’s quality.

- Application Technique: Employ the direct printing method. This ink’s high opacity facilitates efficient wet on wet printing. Ensure each layer gels correctly before overprinting.

- Ink Modification: If you require adjustments to the ink, various additives are available for use. These include curable reducer, process clear, stretch additive, fashion base, finesse base, and more. To gain a deeper understanding of each additive, you can visit this link: Plastisol Inks Additives.

Storage Information:

- Safely store your Plastisol Ink between 65-90°F (18-32°C).

- Keep away from direct sunlight to maintain the ink’s consistency and active properties.

- For peak performance, utilize the ink within one year from its manufacturing date.

Features of Inktek LB9930 Neon Orange Plastisol Ink:

- Non-phthalate: An environmentally-friendly formulation.

- High opacity: Produce vibrant prints with minimal ink layers.

- Low cure: Allows for curing at lower temperatures.

- High-speed: Engineered for rapid printing sessions with superb wet on wet performance.

- Reliability: The ink remains consistent, preventing drying within the screen or bucket, which guarantees prolonged and smooth printing sessions.

Note: Always begin with a pre-test before embarking on a full production run. This ensures you achieve your anticipated results and minimizes wastage. After printing, consistently test the material to confirm the ink has thoroughly fused, assuring the print’s durability and quality. River City Supply and its affiliates bear no responsibility for the misuse of the product. It is the printer’s sole responsibility to test and ascertain that the ink delivers the expected results prior to conducting a comprehensive print run. When printing on 100% polyester, it’s always advisable to utilize a blocker to mitigate dye migration.

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews