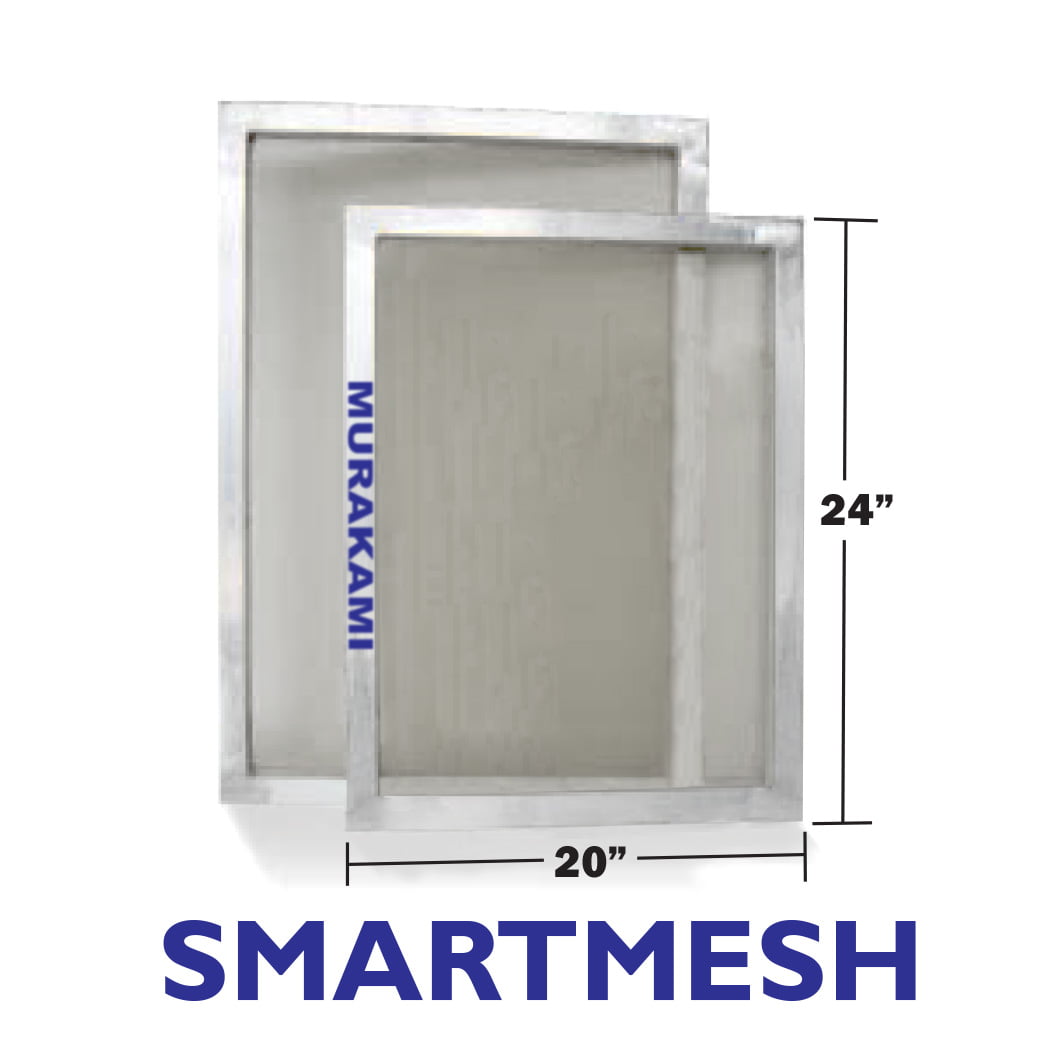

Murakami SMesh Thin Thread 20×24 Frames – In Stock

Key Advantages using Murakami S Mesh:

- Prints PVC/Phthalate well. These new inks require a more open mesh to transfer ink well and not dry in. Extended flood times are possible with S mesh which cleans and re-wets well with a few prints.

- Better base plates – Less squeegee pressure preserves halftones and minimizes dot gain.

- Faster squeegee speeds – Newer PVC/Phthalate free inks shear better at high squeegee speeds. Plastisol base plate squeegee speeds can print faster as well.

- More opacity – Opacity is improved by printing the ink so it lays on the surface of the shirt with less squeegee pressure, not driven into the fabric.

- Softer hand to the print – When ink rests on the surface of the fabric it is more flexible.

- Less Ink Usage – 23-30% less ink used. This cost savings is one of the best ways to save money on your production floor. Ink is your biggest consummable product.

- Less Emulsion Usage – S Mesh has a thinner fabric thickness and uses less emulsion to achieve good EOM, or emulsion over mesh.

- More opaque halftone base plates – Murakami S mesh is capable of halftone counts that are impossible on standard mesh and especially thick HD mesh.

- Fast set ups with a mesh that holds registration and retains good working tensions far longer than inexpensive mesh.

- Superior Prints – Sharp, consistent registration, soft hand feel, better halftone control, all add up to the best prints ever to come off your press.

Note: These screens are very fragile and pop very easily. There are no refunds or returns on S Mesh screens when they break. If you open the box and you have a screen broken on arrival please call within 3 business days of receiving the package so we can work a solution.

$32.33 – $37.33

Description

Today’s screen printing world is in the midst of major change. PVC and Pthalate free inks are being used more and more, but they print far differently than any ink you have used in the past. Plastisol will still have its’ place, but many major clothing merchandisers want a safer ink for their product. This isn’t going to be like switching from one brand of plastisol to another. These inks require rethinking your print recipe of mesh and emulsion. From major athletic and licensed wear manufacturers to new children’s wear requirements these inks are here to stay. Migrating from plastisol to these new style of inks will require a dedication to learning how these inks cure, how to mix and maintain the inks during production and documenting the print recipe to determine best practices for success.

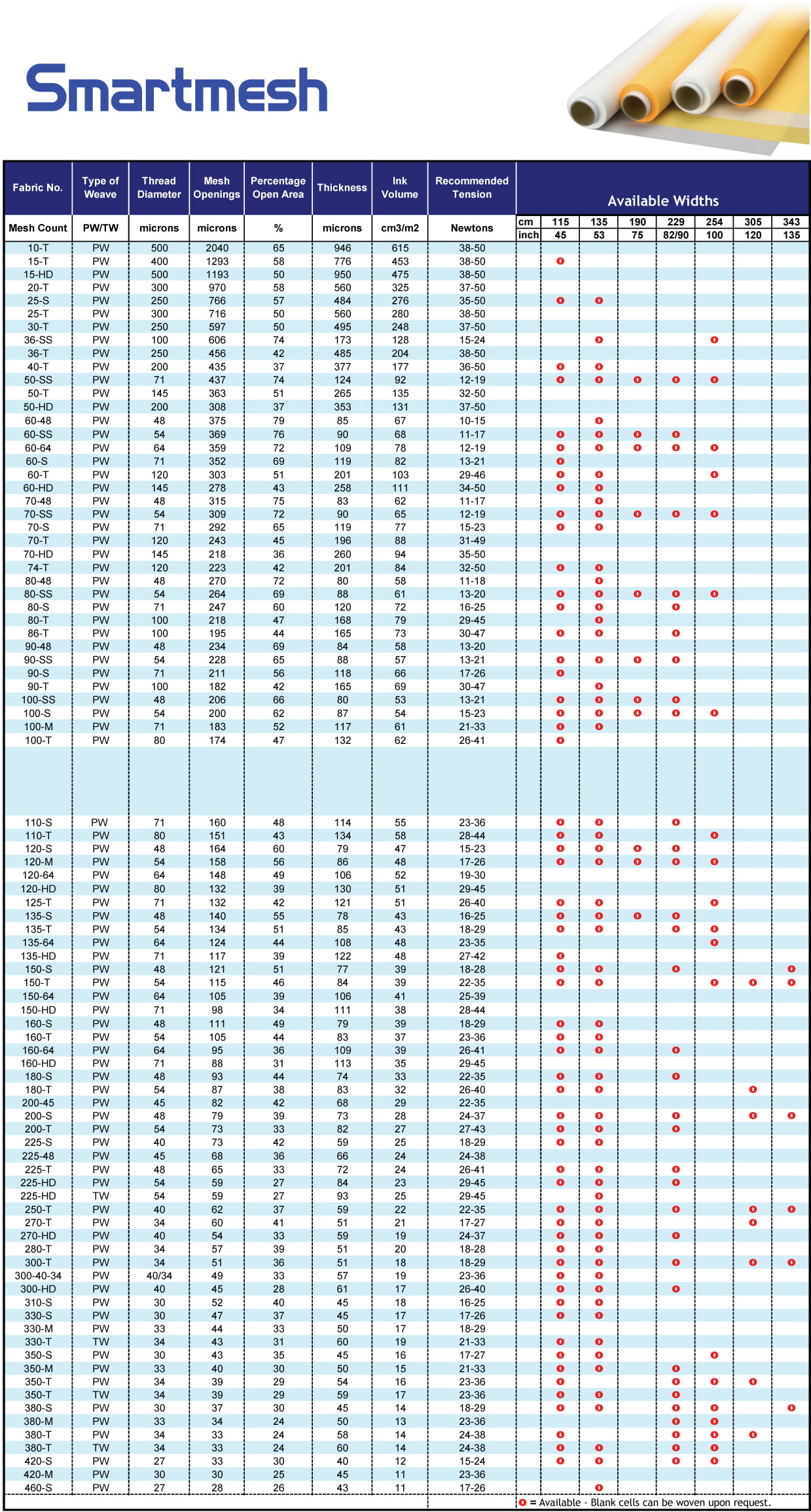

110/T Murakami T Mesh

• 43% open area

• 134 Microns Thick

• Ink Volume: 58 cm³/m²

135/S Murakami S Mesh

• 55% open area

• 78 Micron Fabric Thickness

• 43 cm³/m²

12% more open area than 110T

41% thinner fabric thickness

26% less ink usage

We’ve made the print part easy. We have been promoting S mesh for some time now with great results. The new PVC and Phthalate free inks benefit from the increased open area of Murakami S-mesh. With these meshes you can use less squeegee pressure and faster squeegee speeds to lay down less ink while still yielding great opaque prints. Faster squeegee speeds help these new inks to shear better. This low viscosity ink eliminates the need for a slow printing base plate common with plastisol inks and yields an extremely soft hand feel to the print. S Mesh from Murakami has one other significant advantage; print registration. Murakami’s S Mesh holds registration well. It has properties that aid in keeping your prints on press looking as good as when they were set up at the beginning of the print run.

Murakami Smartmesh retains excellent working tension. Mesh tension is often misunderstood. High mesh tension is not needed for water base, discharge or PVC/Pthalate free inks. These inks shear very easily with a good workable tension of 17-25 newtons. Whether you use stretch and glue or retensionable frames Murakami S mesh retains tension well. 135 Murakami S Mesh with Aquasol HV Emulsion. How is Murakami Mesh different? Murakami Smartmesh thread is made very differently than inexpensive mesh. Lower quality mesh continues to lose tension over the life of the screen and quite often this will happen in the first production run and continue to lose tension until it can’t register well. Murakami Smartmesh will retain a good workable tension level due to a higher quality thread which extends the useful life of the screen. The old saying goes: “You can pay me now or pay me later”. Non stop print production with flawless registration will make you more money in the long run.

135 Murakami S Mesh with Aquasol HV Emulsion.

Murakami 135 S Mesh and Halftones

Can 135 S Mesh print halftone base plates ? The answer is yes. The larger open area and thinner threads allow this mesh to hold a 50 line halftone at 67 degrees. This allows the printer to print PVC/phthalate free inks in simulated process with excellent results. Here is our 67 gradation halftone test.

If you see moire in this image it is due to your monitor and the half tone image interfering. Zoom in to view the 50 line halftone at 67 degrees with little moire. Tonal ranges should be compressed in the art or output to eliminate tonal values below 6% and above 94%.

Printed through Murakami 135 S Mesh

50 Line Halftone, 67 Degrees, PVC Free Inks

Print Courtesy of: Mark Gervais, Ningbo China

S-mesh solves so many print issues that poor mesh creates.

- Print registration – Murakami Smartmesh holds excellent registration for dot on dot screen printing, tight spot color, and 4/C process control.

- Smartmesh from Murakami avoids “AEP”. This is a phenomenon that occurs as mesh warms up in the print process. AEP is “accumulated elongation percentage”. Basically the forces of the squeegee repeatedly pull on the mesh fabric. Murakami Smartmesh resists these forces and avoids losing register to repeated squeegee forces as the mesh warms up during printing.

- Open Area – Murakami Smartmesh exhibits excellent open area percentages while maintaining register with very thin threads. The more the open area the less squeegee pressure needed. This allows any ink, plastisol included, to be laid on the surface of the shirt. When an ink rests on the surface it has more opacity, it can flex better, and it covers shirt fibers better.

- Ink Usage – a recent test at a major printer I visited was done to evaluate ink usage. S mesh is a thinner fabric and has less ink volume being printed. This allowed the company to cut costs on ink consumption and made them more competitive in today’s volume print market. For a large shop this can mean enough savings to buy another press, or expand their operation. Less consumption of raw materials will cover the cost of a better mesh.

- Print Clarity – Too often excess squeegee pressure is needed to clear the screens of inks on typical ‘T’ or ‘HD’ meshes. With S mesh from Murakami the open area allows for less squeegee pressure since ink transfers much easier through thin threads that offer less resistance to the ink eing printed. Dot gain and edge blur are two issues that occur with excess squeegee pressure, minimizing the squeegee pressure helps control both.

Protecting S-Mesh

S-thread requires good screen reclaiming and handling techniques. Train workers on new screen handling procedures, better tools to reclaim with, and different methods to transport the screens from point to point in the production process. If your screen room is a pile of screens, workers oss them around, throw them into the sink, use agressive ozite pads or stiff bristle brushes then your employees need training sessions. These are fine meshes, they require care in handling, they make your bottom line and product better. The last two are good reasons to train your employees to handle with care. S-thread technology is here to stay. Those that adapt will succeed, those that chose to stay a plastisol printer will survive, but those that want better prints with the new PVC/Phthalate free inks at the fastest speed possible will realize their employees need training on how to handle these screens better.

Technical Specifications

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews